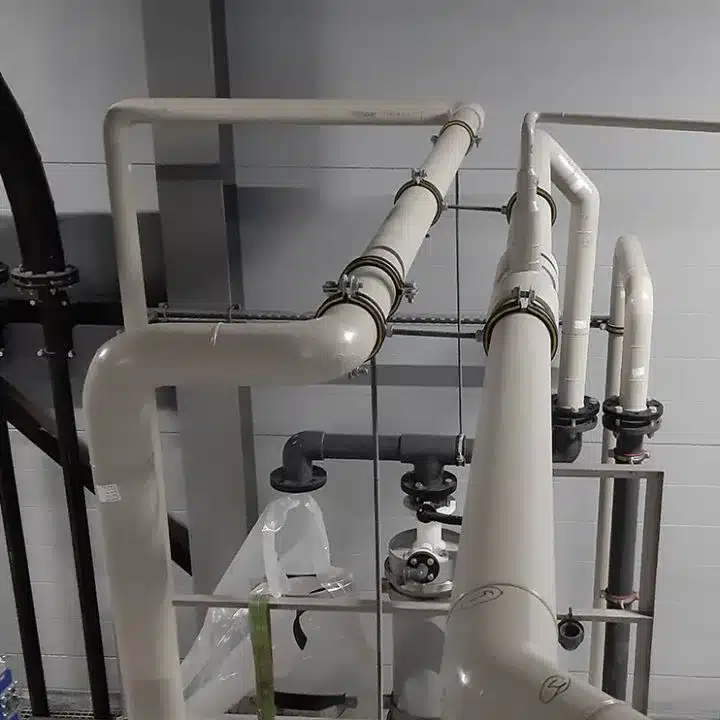

One of the most important components of the industrialized world’s infrastructure is the vast network of pipelines and process piping. Pipelines transport water, sewage, steam, natural gas, LNG and gaseous and liquid hydrocarbons. Nowadays plastic pipes play an important role in almost every industrial process.

The term “process piping” generally refers to the system of pipes that transport process fluids (e.g., air, steam, water, industrial gases, fuels, chemicals) around an industrial facility

Pipelines and process piping have traditionally been made of metals such as steel, cast iron or copper. They are subject to corrosion over time, which inevitably leads to high maintenance costs and even plant failure/downtime. The chemical resistance and long lifespan of plastics ensure efficient, economical, and safe solutions.

The use of plastic materials is growing, as they can offer:

Safety first

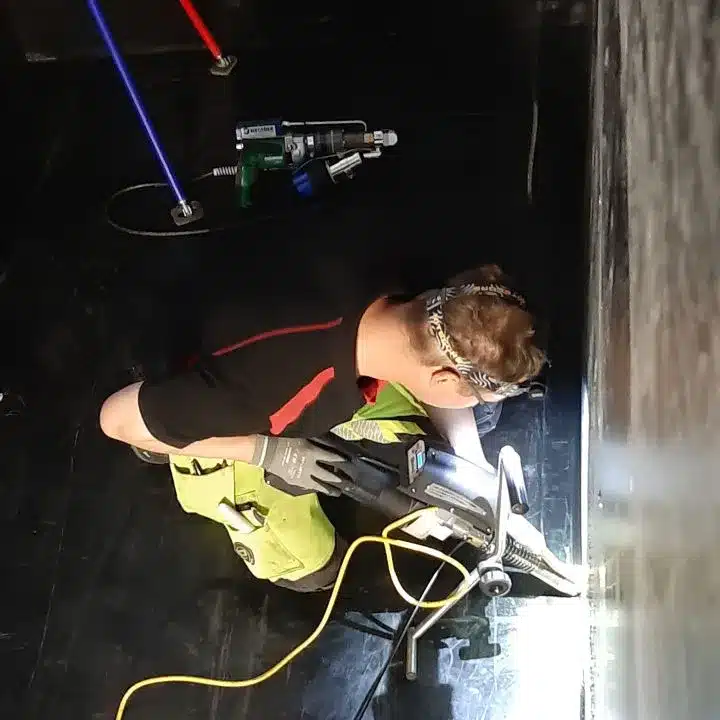

Given the potential consequences associated with pipeline and piping failures, mitigation of failure risk is of critical importance. Our project team will provide in-depth technical knowledge that will help efficiently minimize risks during the design, layout, construction, and operation of pipelines and piping systems. This includes an adequate material selection (according to the media, temperature, pressure and environmental conditions), a correct pipe section dimensioning and choosing the most convenient welding method.

Plastics for any application

At Atolli, you will find a depth product range and a huge variety of plastic materials, as the properties of each polymeric material will mainly define the applicability of a system. Relying on more than 50 years of experience and a good understanding in the process industry, our experts will help specifying the material compatibility of a particular application. When selecting the materials and systems close collaboration between the user and the manufacturer is essential.

At Atolli, you will find a wide range of products and materials. Our experts’ over 50 years of experience and good understanding of the process industry ensure the right solutions in the right places.

Our installers have passed the EN 13067 Qualification Tests (PED) and follow Finnish Safety and Chemicals Agencys’ (TUKES)

MO-FR 9:00 – 15:00

SA-SU CLOSED